Welcome to visit Fortaco at Tampere Subcontracting Fair 24-26 September 2019

The traditional event with 20.000 industrial professionals takes place at Tampere Exhibition Center.

Increased uncertainty on the global market makes forecasting of future challenging. However, Fortaco is ready for this challenge through productivity improvements and machine investments to increase production automation. Our operational excellence programs ensure that our customers receive products at the right time, with the right quality and at the right price.

One of our most significant ongoing investments is a factory expansion in Narva with 10.000 m2 and new equipment. During the past years, Fortaco has also invested in several welding robots, machining centers and production lay-out improvements to ensure our position as a professional and reliable partner in our industry.

Fortaco Technology has been kicked-off as planned and it is well received by our customers. The first common R&D projects are ongoing. Fortaco is expanding cabin technology and manufacturing presence into the Asian market. The partnership with Tata AutoComp is enabling OEMs in India to use Fortaco's cabin technology and knowledge on this fast-growing market area.

Welcome to exchange ideas and news with Fortaco people on our stand A630.

See you in Tampere !

Marcus

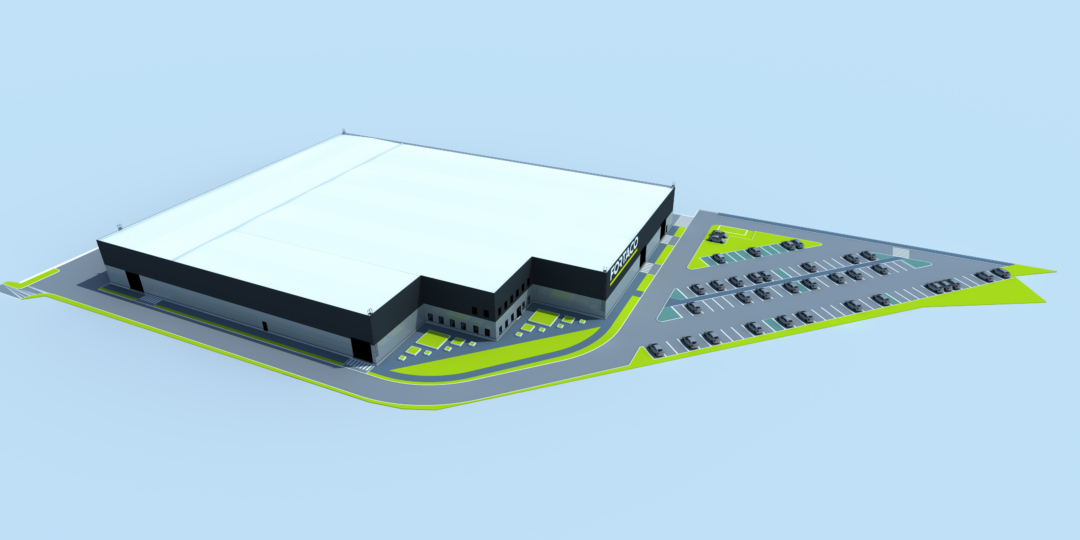

Fortaco invests in increased steel fabrication capacity at Fortaco Estonia OU

Fortaco has started a capacity extension project of over 10 million EUR in Narva, Ida-Virumaa. The investment will consist of a 10.000 m2 factory extension and new equipment. The construction work begun in July 2019 and it is scheduled to be finalised within one year. The investment is supported by the Estonian government.

Read the Press Release

First half of 2019 - Summer Greetings

The first half of 2019 has been exciting, as usual. The world offers higher focus on the environmental care, higher degree of digitalization and intensive geopolitical discussions like Brexit, global versus regional, trading tariffs etc.

When entering year 2019 Fortaco was cautious in respect of market development. We have experienced a mix of strong growth, stabilization and some decline among our customers. The outlook for the second half of 2019 looks promising, we are expecting to continue delivering a profitable growth. Fortaco offers services from concept to manufacturing, in addition we see the value add for our customers of being a strong technology and R&D provider. Fortaco has launched an EU financed steel fabrication project to develop future production materials, manufacturing processes and product features.

Fortaco participated Bauma exhibition in Munich mid-April, world’s largest off-highway exhibition with more than 620.000 visitors during five days. At the exhibition Fortaco launched the redefined branding concept to further enhance Fortaco’s core values of excellence and reliability. Our stand was visited by the current but also new customers and suppliers. We discussed about Technology, Vehicle Cabins, Steel Fabrications and Vehicle Assemblies.

Fortaco has reached an important momentum, we have announced a collaboration with Tata AutoComp Systems with the aim to offer safety cabins for off-highway vehicles in India, based on technology, design and specifications developed by Fortaco. Our joint strengths will build a strong foundation for the future.

I am proud to be a member of the highly experienced people team across all operations at Fortaco. To meet with customers and suppliers gives continuously energy to explore how we can together re-shape the industry and make it more innovative and a safer workplace. Fortaco has Trust in Tomorrow.

Enjoy the summer with your families, nearest and friends to charge batteries for the exciting second half of 2019.

With best regards,

Lars Hellberg

President & CEO

Fortaco signs Agreement with Tata AutoComp India

Tata AutoComp signs an agreement with Fortaco Group - aims to manufacture safety cabins for off-highway vehicles in India.

Tata AutoComp Systems Limited, India’s leading auto-component conglomerate and Fortaco Group, the leading European strategic partner to the heavy off-highway equipment have signed an agreement, where in Tata AutoComp will manufacture Safety Cabins for off-highway vehicles in India.

Read the Press Release

Fortaco teams took part in charity run in Wrocław

For the fourth time Fortaco teams have participated Company Run, which took place 13th time in Wrocław. This is the charity run, organized for employees of all size of companies in Poland. In addition to improve physical activity, the charity run is arranged for helping handicapped kids.

Over 400 companies and 10 000 runners took part in this event. Four teams from Fortaco took the challenge. Link to an official web page: https://biegfirmowy.pl/ (in Polish).

Fortaco factory in Kurikka is non-smoking

Fortaco’s factory in Kurikka is a non-smoking area since 1 January 2019. Smoking is forbidden in all factory area. This applies to all Fortaco employees, our customers and other stakeholders visiting our facilities. There is one dedicated place outside of factory area where smoking is only allowed.

Fortaco is encouraging employees to stop smoking. Occupational health care professionals are providing support, and Fortaco gives financial compensation to nicotine replacement products.

Health and safety are the top priorities at Fortaco!

4th International VDI Conference - Connected Off-Highway Machines

The 4th international VDI Conference “Connected Off-Highway Machines” will take place on 14 – 15 May 2019 in Dusseldorf. Fortaco will also be there, you are welcome to visit our stand No. 6 and meet with Aki Komulainen, Director Cabin Technology, Raphael Dubiel, Sales Director Central Europe & Benelux and Frank Elert, Sales Director Central Europe.

Conference is aimed at engineers, designers and specialists from mobile machine manufacturers and suppliers in the off-highway industry. Conference provides a professional forum for all experts working in the field of connected off-highway machines, automation and IT for mobile machines to exchange experiences and ideas.

See you in Dusseldorf 14-15 May!

Thank you for visiting us at Bauma 2019

We would like to thank you for visiting us at Bauma 2019. Bauma is really the heart of the industry. The show was a success again, the best place to meet with customers, partners and colleagues within the industry.

Once more - thank you and see you again in Munich in 2022!

Fortaco at BAUMA Exhibition

BAUMA exhibition collects together professionals in construction, building materials and mining machinery industries.

Exhibition takes place in Munich 8 – 14 April. BAUMA in Germany is the world’s largest meeting place with 0.6 million visitors.

This is the second time Fortaco participates this most important marketing event of the year. All our business areas, Fortaco Technology, Steel Fabrication, Vehicle Cabin and Vehicle Assembly will be presented at the show. You can meet our team of professionals at Fortaco stand 403 in Hall A6. We are there from Monday to Sunday 8 – 14 April.

Reserve time already now in your calendar, and make sure you are on the map what happens in this industry!

Business Site Wroclaw - professional manufacturing partner for steel components

Business Site Wroclaw produces key components for our world-class customer products. These components are used in the most demanding applications and environments. Every day, we are challenged to improve our product performance, reliability, costs, and time to market to meet the customer requirements of tomorrow. At Wroclaw factory, we are specialized in selected key components that weigh up to 15 tonnes. We are continuously investing in the latest technologies and high competence in order to respond to our customers’ needs on the market, and to meet productivity and capacity requirements.

During the recent years, Fortaco has invested extensively in the new production machinery and welding automation. The capacity of robot welding has been continuously increased to ensure productivity and to keep business growing also in the coming years.