Long tradition of cabin development in Kurikka

Learn more about cabin development and manufacturing in Kurikka, our biggest factory for cabin manufacturing and the home of CabTech. This video gives you a full insight into our Business Site in Kurikka. The factory combines a long tradition of cabin development and manufacturing in a modern factory environment.

Our recent investments into the factory layout, robot technology and surface treatment process are ensuring efficient and flexible production processes of world-class.

Fortaco is steaming ahead in busy market

Year 2017 has been successfully closed, and in 2018 Fortaco is steaming ahead with a full speed in the overall busy market. Let me recap some key highlights from 2017 and share our key priorities going forward this year.

Increasing market demand

There were only a few economists some years ago, who could foresee the general pick-up on the market, realizing towards the end of 2016 and continuing the full year of 2017. As a result, Fortaco experienced an increasing demand on most of our customer segments – especially amongst mining, material handling, forestry and construction. The increased demand was converted into the growth of net sales, in the excess of 20% in 2017. As the capacity is not unlimited on short-time, this growth of net sales often meant working 24/7 and long days at several Fortaco Business Sites. I would like to take this opportunity and express my gratitude to all our customers and Fortaco people for the hard work done.

Fortaco’s position and strategy crystallizing

In 2017 the position and strategy of Fortaco have been crystallizing. Just to reconfirm, Fortaco is the leading brand independent strategic partner to the heavy off-highway equipment and marine industries offering Technology, Vehicle Cabins, Steel Fabrications and Vehicle Assembly. Fortaco’s pledge is to provide our customers with the industry leading mix of quality, delivery accuracy and cost and the highest safety standards. We are continuously challenging our way of working to make tomorrow better than today, and we benchmark ourselves to the automotive industry standards. As an example of our development, a new Fortaco Technology business area was established in 2017 providing our customers with additional value and services across the whole Fortaco product offering portfolio.

Fortaco continue building up capacity in 2018

In 2017, Fortaco started increasing the overall level of investments in its operations. Consequently, several important capacity investments were finalized or decided, including several new welding robots and machining centers, a new laser cutting machine and a new press break and large-scale layout change project in one of the Business Sites. Fortaco will continue building up capacity also in 2018, several new capacity investments have already been decided during the first quarter. After refinancing was fully completed during the first half of 2017, Fortaco is financially a sound company and well positioned for untapped market opportunities.

Fortaco - the premium supplier

Dear valued customer, Fortaco is the premium supplier on the market, our commitment is to act accordingly every day. Going forward 2018, ensuring the industry leading delivery accuracy is the highest priority on our agenda. We do have continued good performance at most of our Business Sites, whereas delivery accuracy has not been where it should be at some Business Sites. We are working actively to ensure the needed capacity and supplies in accordance with the customer promise. Together we will make it.

Kimmo Raunio

Senior Vice President & CFO

The future of welding - 40 robots and new approach from design to manufacturing

The next wave of robot investments constitutes a significant landmark in Fortaco’s history. The number of robots raised to 40 after the three new welding robot investments at Business Site Janow Lubelski, Kalajoki and Wroclaw.

This is an inevitable development in the era of modern manufacturing and digitalization. In the off-highway industry the robotization of manufacturing is a real challenge. The combination of high variability, seasonality and low volumes are setting the framework for a flexible manufacturing system. In our industry, volumes are not measured in millions of produced units but rather 10 – 1000 units per year.

Many of today’s products have been designed without thinking the use of robotization in manufacturing processes. In addition, the new generation of engineers has limited experience of manufacturing environments, technologies or processes.

The new Fortaco Technology unit has been created as a response to today’s challenges among many of our customers within the off-highway industry. Our Manufacturing Technology team is enabling our customers to realize the full potential of robotization in manufacturing . We are working closely with our partners in the robotics to secure that we make tomorrow better than today.

We invite and challenge our customers to involve Fortaco Technology team already in the concept and design phases to enable the best result. Your success is important.

With our 40 robots at the Fortaco factories we are committed to secure the technology shift.

Join us in this interesting journey!

Prime Minister of Estonian Republic visited Fortaco in Narva

Mr. Jüri Ratas, Prime Minister of Estonian Republic has visited Narva and Narva-Jõesuu to meet the local businessmen and representatives of city authorities.

During his visit Mr. Ratas met the town government in Narva-Jõesuu and companies in Narva, like Fortaco Estonia. Prime Minister was received by Mr. Lars Hellberg, President & CEO of Fortaco Group, Mrs. Larissa Shabunova, Managing Director of Fortaco Estonia and Mr. Kimmo Raunio, Senior Vice President & CFO of Fortaco Group.

The purpose of the visit was to discuss development prospects in Ida-Virumaa region, where also Fortaco Estonia is located and playing an important role in development of the whole region.

Fortaco Estonia was selected as the venue to introduce the governmental program of Ida-Virumaa development support. The program will be started as from July 2018 with Narva business representatives.

A factory tour was included in the Prime Minister programme. Mr Ratas was very much impressed about the high level of production organization and expressed his thanks to the company management for a great job done.

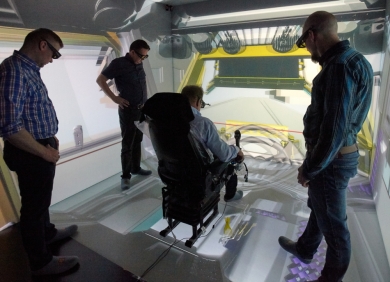

New Fortaco Technology unit

Fortaco Technology is an integrated part of Fortaco offering allowing our customers and Fortaco work together at an early phase of value chain.

Fortaco CabTech unit has proven to be a success since many years. Based on the years of experience with our CabTech team we are expanding activities and supporting our customers with design, engineering, process and project management know-how.

A new Fortaco Technology unit is providing this know-how and capabilities not only for Cabin, but also for Steel Fabrication and Vehicle Assembly businesses. We are supporting development of manufacturing technologies and providing advisory services in “Design-to-Manufacture” area.

Project Management skills and modularization methodology are part of Fortaco Technology.

Mr Rafal Sornek has been appointed Senior Vice President and Head of Fortaco Technology as from 1 January 2018.

This is Fortaco - learn more about us - watch the video

Learn more about Fortaco Group, who we are and what we do. This video gives insights into how our technology know-how, engineering skills and manufacturing facilities for cabins, steel fabrications and vehicle assemblies benefit our customers.

We challenge ourselves to make tomorrow better than today and solve problems faster and at a deeper level than our competitors. We have the right quality, the right delivery accuracy and the right price.

Together we want to reshape the way things are produced.

High pressure and positive outlook in the manufacturing industry

Thank you for visiting Fortaco at ELMIA!

Fortaco has been exhibiting at Elmia Subcontractor Trade Show in Jönköping for the very first time – and it feels already the place to be.

New production technologies, like additive manufacturing, IoT and digitalization in manufacturing are clearly trending also in the heavy equipment industry.

The manufacturing industry is going by full speed ahead and facing a technological shift which will change society. That was clear when Elmia Subcontractor - Sweden’s biggest industry event - reinforced its position again as the leading marketplace for new business deals.

We were happy to experience a good sprit among the visitors and our fellow colleagues within the industry.

Thank you for making the exhibition a success, see you next year!

Fortaco and GE expanding operations in newly built factory in Wrocław

Dozamel Sp. z o.o. – a company managing Wrocław Industrial Park - has opened a new industrial facility with the production and office spaces. The new building consists of three production halls with the total area of 3.800 m2 and a four-storey office and social building with 2.400m2.

The whole production space in the new building is rented by Fortaco and GE Electric. Fortaco has rented two production halls, in total 2.400 m2 and GE Electric has rented the third production hall, 1.400 m2.

An opening ceremony took place on 6 November, the special guests of the event were:

Andrzej Adamczyk, Minister of Infrastructure and Construction

Paweł Hreniak, Governor of Lower Silesia

Lars Hellberg, President & CEO for Fortaco Group

Beata Stelmach, President of the Management Board, GE Poland and the Baltic States

For the development of Fortaco Business Site in Wrocław the new space is crucial, it will help to follow a market growth and changes, as well as increase machining, welding and assembly capacity.

With the new machining center installed in the first production hall Fortaco can offer high-precision and high-flexibility and cover a wide spectrum of machining requirements requested by our customers. In addition, in the first production hall is located a welding free assembly area for the final assembly processes and further assembly business development.

The second production hall will be filled-in by rotators and fixtures to be used in welding processes that are fulfilling the growing needs for the welding capacity.

In the third production hall GE Electric is doing installation, programming and testing for control cabinets in power industry, including generator and turbine regulator cabinets.

Official ribbon cutting, from left: Paweł Hreniak (Governor of Lower Silesia), Beata Stelmach (President of the Management Board, GE Poland), Andrzej Adamczyk, Kazimierz Smoliński (Vice Minister), Lars Hellberg (President & CEO for Fortaco Group), Pawel Kowalczewski (CEO for Dozamel)

Fortaco is investing in future at Kurikka factory

Fortaco has invested in training and personnel development at Business Site Kurikka during the recent years. We have invested 1.5 M€ in the additional automation on a surface treatment process and a factory lay-out to improve material flow. These investments will increase production efficiency and enable business expansion with new projects and customers in the future.

Fortaco has also invested in a product development, we have opened a new modern product development unit, Kurikka Technology Hub. New premises allow us even more intensive product development and prototyping, and manufacturing of related tools and jigs.

For more information, please contact:

Arto Aro

Managing Director

Fortaco Cabins & Vehicle Assembly, Kurikka

arto.aro@fortacogroup.com

Aki Komulainen

Director, Fortaco Technology

aki.komulainen@fortacogroup.com

Fortaco at ELMIA trade show 14-17 November

Northern Europe's leading subcontracting trade show 14-17 November 2017 in Jönköping, Sweden

Elmia Subcontractor fair brings together manufacturing industry experts under the one and same roof. Fortaco team is excited about an opportunity to meet all our customers and other stakeholders at the fair, you can find us at a booth D03:14.

Fortaco mission is to reshape the way things are produced. During the recent years Fortaco has been focusing on our core competences: Operator Cabins, Steel Fabrications, Vehicle Assembly and Technology. Fortaco has a wide industrial knowledge across different industries. Now we are expanding our technology know-how into steel fabrications as well. Everything from design to manufacturing is included in our concept.

Please come and visit us, the Fortaco crew is happy to tell you more about an unique opportunity to take the full advantage from design to cost.