Tata AutoComp signs Memorandum of Understanding with Fortaco Group

Tata AutoComp signs Memorandum of Understanding with Fortaco Group -

aims to expand its offering to the farm equipment segment.

The farm equipment market in India is developing and requesting customized solutions in cabin design and user friendly working ergonomics as well as safety for end users. The market is expected to continue growing and supporting domestic and international need of excellent farm equipment products.

About Tata AutoComp Systems Limited

Tata AutoComp Systems Limited (Tata AutoComp), promoted by the Tata Group, provides products and services to the Indian and Global automotive OEMs as well as Tier 1 suppliers. Tata AutoComp has own capabilities in Automotive Interior & Exterior Plastics, Composites, Sheet Metal Stampings as well as Engineering and Supply Chain. Tata AutoComp has 7 joint ventures in partnership with leading companies from the Global Auto Component Industry through which it manufactures and markets automotive components and systems like engine cooling solutions, automotive batteries, rear view mirrors, command systems, HVAC, exhaust and emission control systems, seating systems and electronic solutions for passenger and commercial vehicles as well as suspensions for heavy commercial vehicles. Tata AutoComp has 34 manufacturing facilities spread across India and 8 facilities spread across North America, Latin America, Europe and China.

About Fortaco Group

Fortaco Group is the leading brand independent strategic Tier 1 partner to the heavy off-highway equipment industries offering technology, vehicle cabins, steel fabrications and vehicle assemblies. Fortaco Group has operations in 8 European Business Sites and 3 Technology Hubs, which are supporting our global customers.

AgriTech exhibition

At the agriculture exhibition “AgriTech” on 31 August - 2 September in Bangalore Fortaco and Tata AutoComp displayed together a new cabin designed and manufactured to address the requests and needs on the farm equipment market in India. The new cabin is based on the latest global cabin product and manufacturing technologies securing excellent customer experience and manufacturability.

For more information, please contact:

Mr. Lars Hellberg

President & CEO

Fortaco Group Oy

Ph: +358 40 572 9488

lars.hellberg@fortacogroup.com

Mr. Shvetal Diwanji

Vice President Corporate Communications

Tata AutoComp Systems Limited

Ph: +91-20-66085119

Mob: +91- 9604400266

shvetal.diwanji@tacogroup.com

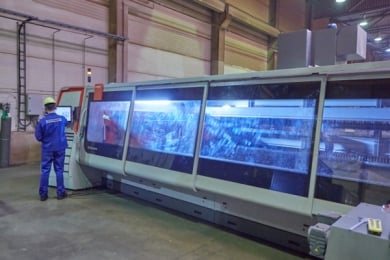

Kersti Kaljulaid, President of Estonia visited Fortaco factory in Narva

President of Estonia Kersti Kaljulaid visited Fortaco factory in Narva. President was welcomed by Lars Hellberg, President & CEO for Fortaco Group, Larissa Shabunova, Managing Director for Fortaco Estonia OU, Kimmo Raunio, CFO for Fortaco Group and Hannu Heinonen, Deputy Head of Mission, Finnish Embassy in Estonia.

After the presentations of Fortaco Group, Fortaco Estonia and Honorary Consulate of Finland in Narva President Kaljulaid was invited to see production facilities and the site of future factory which is under construction. During the tour at production President Kaljulaid was offered an opportunity to make a souvenir to herself with the official Estonia 100 years -logo. President Kaljulaid pressed the button on Bystronic Laser Cutting Machine and in a minute a blank souvenir was ready. By the end of the factory tour the souvenir was ready bended and painted. President Kaljulaid was positively surprised about the speed and quality of factory processes.

President Kaljulaid highly appreciated the great development of Fortaco Estonia, being the second biggest and the best employer in the Narva region. She was also surprised about the investment programs and technologies implemented and the complexity of products manufactured at Fortaco factory in Narva.

President Kaljulaid is wishing the best success for the Fortaco factory in the future.

New Operator Cabin for Agricultural Tractors

Fortaco is introducing a new new Operator Cabin for agricultural tractors at AgriTech Exhibition in Bangalore, India on 31 August - 2 September 2018.

The new cabin is based on the latest global cabin product and manufacturing technolgies securing excellent customer experience and manufacturability.

Modern look, rigid and durable structure are combined in this state-of-the-art operator cabin. In addition to safety, comfort and user friendly working ergonomics as well as cost effectiveness have been the key factors in the design process.

Cabin can be easily adapted to the most common agricultural tractor brands.

Fortaco to exhibit at Subcontracting Fair in Tampere, Finland

Fortaco will exhibit at Subcontracting Fair in Tampere, Finland. The event takes place on 25 - 27 September at the Tampere Exhibition Center.

We have seen a rapid growth on the market during the last years, which has stretched supply chains into the maximum. The busy market situation has created challenges for both OEMs and their suppliers. In order to meet market expectations, Fortaco has continued our Operational Excellence program and made a number of investments into the production lay-outs, manufacturing technology and automation to boost capacity across our manufacturing footprint. Investments will be continued also this year – one big robot welding cell is about to be installed in Kalajoki factory, and more welding robots and machining centers have been taken into operation at our factory in Narva.

Fortaco has launched a new Fortaco Technology unit to help our customers also in steel fabrication and manufacturing technology, in additon to cabin technolgoy. We want to offer the best in class product design and manufacturing technology in one package.

Please visit our stand and meet with our technology team to see possibilities within virtual and augmented reality in cabin design and quality control. The new reality of R&D is close to our heart. Check out the recent blog by Rafal Sornek, Senior Vice President, Fortaco Technology.

Please come and discuss with our team, what new we can offer for your company in manufacturing and development of technology.

See you in Tampere!

Hall A - Fortaco A630

New Correa CNC machining center started at Fortaco Estonia

A new machining center has been started up at Fortaco Estonia during summer.

Fortaco continue strengthening machining capabilities at Narva factory, the new machine is a big brother of the earlier Correa Fox 40 machine investment.

The Correa Fox 50 bridge type of machine is the third machining investment, which has been started this year to be able to meet the increasing demand on the market.

The movements are: Longitudinal = 5 000 mm, Cross = 3 750 mm, Vertical = 1000 mm. The maximum weight of a work piece is 15 tons.

The new production technology, together with skilled operators, is supporting Fortaco mission to create added value for our customers by reshaping the way things are produced.

Modern manufacturing of steel fabrications for off-highway industries in Janow Lubelski

Business Site Janow Lubelski was established in 1976. Today, we are more than 400 highly motivated professionals focusing on the development and production for our world-class off-highway equipment customers globally.

Fortaco is heavily focusing on operational excellence and good cooperation with our customers. With the latest manufacturing technologies and profound knowledge and experience we ensure our services are delivered right time, with right quality and right price.

Learn more about Fortaco operations in Janow Lubelski

Fantastic, sunny summer started already in May and it is time to enjoy holidays

Fortaco’s story continued to develop during the first half of 2018. Market remained overheated and growth gave both positive results and some issues, which needed attention. Our primary focus area was the growth, how to manage it combined with stabilization. I would like to express my thanks to Fortaco’s customers, suppliers, partners and all the great team members at Fortaco who are working together.

What are we expecting in the second half of 2018? I would say, many known and some unknown issues. The known issues are the well-defined customer demand, our ‘Make Tomorrow Better’ -actions and our own people capabilities. There are also some unknown issues, like the world trade barriers impacting on Fortaco’s business, and the high turnover of welders in some countries. Are we going to experience steel price stabilization, and is the offshore market returning like mining 12 months ago. I would like to say that the known and unknown issues are part of daily business and by staying focused we can all benefit together.

New Fortaco Technology unit

I have proudly experienced Fortaco’s mission in talks with our current and new customers - create value add for our customers by reshaping the way things are produced - and what it can offer on short- and long-term. I can see electrification to be one of many power sources instead of diesel power, and the new technology by autonomously driven vehicles addressing the need for change. Fortaco’s response is the new Fortaco Technology unit, we are experiencing an increased need by our customers to change and adapt into the new situation. This is just a positive change and an integrated part of the change of macro economics, which is targeting on more environmentally friendly future.

I am also proud to experience continuous work executed by Fortaco’s people to ‘Make Tomorrow Better Than Today’. It is important to reach ‘zero’ injuries and ‘zero’ quality defects, as well as deliver products as promised. Fortaco is in an early stage of the process. We benchmark the Toyota way of working and we know that Toyota is also in the early stage to make tomorrow better than today.

Value adding strategy

Fortaco has developed a new value adding strategy during the first half of the year to increase customer value. Our current strategy is based on the cost plus calculation, but the future model is based on value creation. The Fortaco team will start to discuss the future model together with our customers. We have spent time to further understand what our customers want from a strategic partner like Fortaco. Based on the talks and workshops we are ready to discuss our customers’ needs and the flexibility of components, module assemblies and complete vehicle assemblies.

It is time to celebrate Fortaco’s 5th holiday period, we are still young company and we intend to be young in our mindset. Let me wish our customers, suppliers and partners - and most importantly - Fortaco people a great summer and holiday with your nearest. The second half of 2018 is about to start, let us have fun together and shape the future.

With best regards,

Lars Hellberg

President & CEO

Fortaco Estonia continues with investments - new machining centers taken into use

Fortaco Estonia has taken into use two new machining centers to secure the future business growth. The new machinery will improve accuracy and quality for the manufacturing process and ensure increasing demand from the market.

The Huyndai horizontal boring machine KBN135L makes it possible to handle pieces up to 10 tons of weigh. Huynday is capable to handle movements up to X = 3 000 mm, Y = 2 000 mm, Z = 1 600 mm and W = 700 mm.

The Correa Fox 40 bridge type of machine represents a new and innovative concept with the speed and precision of high performance machining. There is a unique system, which is controlling temperature generated in the vertical axis of the machine. Correa has versatile capability up to X = 4 500 mm, Y = 2 500 mm and Z vertical = 1700 mm. The maximum weight of a work piece is 15 tons.

Together with the zero point fixing and pallet system the both machines are improving production efficiency and machining quality at Business Site Narva.

Fortaco Estonia strengthens prefabrication capacity by investing in new laser cutting machine

Fortaco Estonia has taken into use the brand new Bystronic ByLaser 6000 -cutting machine to secure capacity for ready-to-weld parts. The new machine is using the latest laser technology with software solutions that enables the lean manufacturing processes. The machine will improve the quality of cutted parts and ensure effective robot welding process. In-built automatized features increase the utilization rate and make it possible to run the machine unmanned as well.

The new laser cutting machine is part of Fortaco Estonia’s investment program to ensure a sustainable growth together with Fortaco’s key customers.

Fortaco Business Site in Narva is one of the biggest Steel Fabrication companies in Estonia. Our factory is specialized to make components for material handling, forestry and mining industries, like booms for cranes, crappers and frames. Fortaco factory in Narva is using about 10.000 tons of steel plates per year, which are processed to high quality products by over 500 employees. Fortaco Estonia is the competence center of high-strength steel processing, as it requires special skills and experience in all phases of manufacturing processes.

The cutting area of the machine is 4090 mm x 2060 mm and maximum plate thickness is 25 mm.

New General Manager - New Era at Fortaco in Kurikka

Mr. Olli Koivisto, B. Sc. in Industrial Engineering and Management, has been appointed as General Manager for Business Site Kurikka as from 28 May 2018.

Fortaco Business Site in Kurikka compromises two businesses - Fortaco Cabin and Fortaco Vehicle Assembly. We combine a long tradition of cabin development and manufacturing in a modern factory environment. The recent investments into the factory layout, robot technology and surface treatment process are ensuring efficient and flexible production processes of world-class.